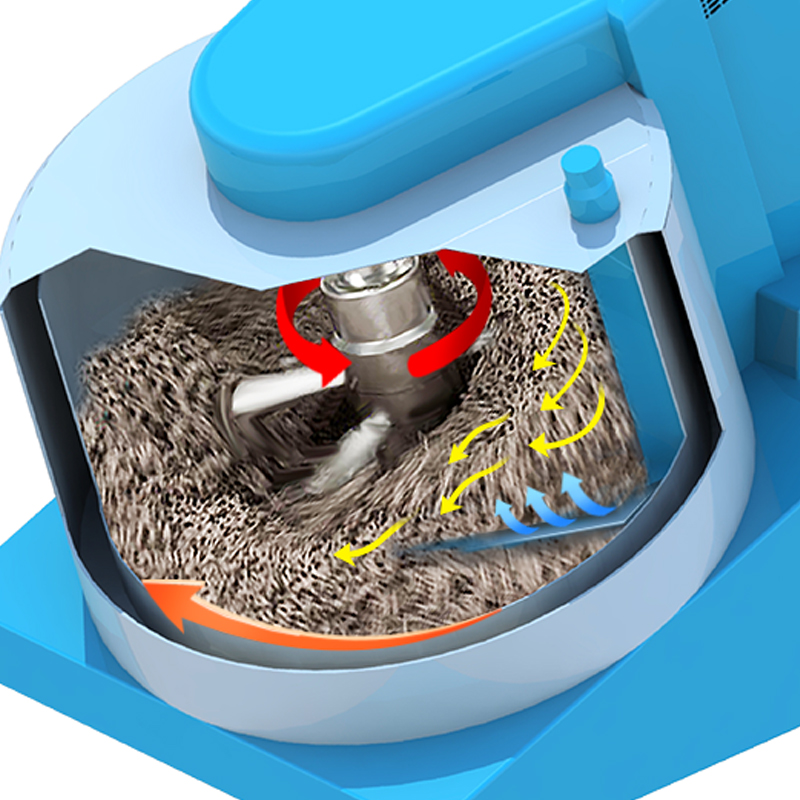

With the continuous development of industrial technology, the demand for refractory materials is increasing year by year. In the production process of refractory materials, mixing is a very important link. Traditional mixing methods often require a lot of manpower and time, and the mixing effect is unstable. With the advent of the Envison intensive mixer, this problem has been effectively solved.

1. High efficiency: Envison powerful mixer has the ability of high-speed mixing and high-efficiency mixing. It can mix a variety of raw materials evenly in a short time, greatly improving production efficiency.

2. High precision: Envison powerful mixer adopts advanced control technology, which can accurately control the proportion and time of mixing, thereby ensuring the precision and stability of mixing.

3. Energy saving and environmental protection: Envison powerful mixer adopts energy-saving technology, which can reduce energy consumption and emissions, and meets the environmental protection requirements of modern industry.

4. High reliability: Envison intensive mixers use high-quality materials and advanced manufacturing processes, which can operate stably for a long time and reduce maintenance and failure rates.

In the refractory industry, Envison intensive mixers have a wide range of applications and can be used to mix various powder raw materials, cement, additives, etc. It can improve mixing speed and mixing quality while saving labor and time costs. For refractory material manufacturers, using Envison intensive mixers can also improve product quality and competitiveness, production efficiency and corporate image.

At the same time, the Envison intensive mixer is also highly intelligent and can achieve remote monitoring and control, greatly improving the controllability and safety of production. This is very important for enterprises, as it can help them better manage and control the production process and improve production efficiency and quality.

In short, the application prospects of Envison intensive mixer in the refractory industry are very broad. It can not only improve production efficiency and product quality, but also reduce production costs and save energy, complying with the environmental protection requirements of modern industry. It is believed that as time goes by, more and more refractory material manufacturers will choose to use Envison intensive mixers and apply them to production, thereby achieving better development and competitive advantages.